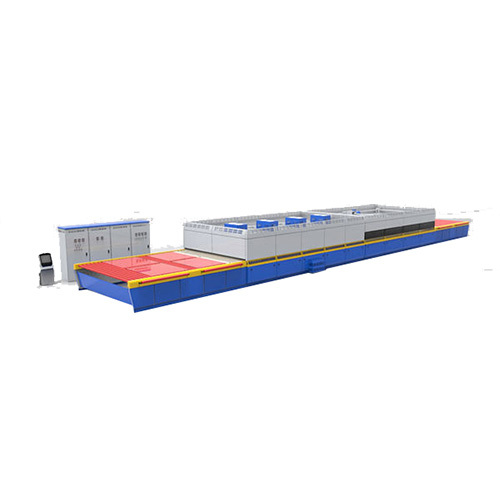

Convection Tempering Furnace

Product Details:

- Product Type Convection Tempering Furnace

- General Use Industrial

- Material Stainless Steel

- Computerized No

- Automatic Yes

- Control System PLC Control

- Voltage 220-440 Volt (v)

- Click to view more

X

Convection Tempering Furnace Price And Quantity

- 1 Unit

Convection Tempering Furnace Product Specifications

- Yes

- Convection Tempering Furnace

- White and Blue

- ECO Friendly

- 220-440 Volt (v)

- 1 Year

- Industrial

- Stainless Steel

- PLC Control

- No

Convection Tempering Furnace Trade Information

- Telegraphic Transfer (T/T) Cash Advance (CA)

- 30 Unit Per Month

- 45 Days

Product Description

"The heating method of glass in the tempering furnace is heating on the upper and lower sides. The convection tempering furnace also has a convection device at the lower part to strengthen the heat transfer at the lower part. In this way, the upper and lower surfaces of the glass can be heated synchronously, so that the glass heating quality is more perfect and the production efficiency is higher.

Technical parameters:

The Super Cycle features over the others: Highest heating speed, (capacity) => lowest labor and energy costs.

- Roller temperature stabilization, (bottom convection by blowers) => easier operation, better quality and higher yield at lowest cost.

- Suitable for practically all glass types, capable for triple silver glass, emissivity 0,02-0.03. Accurate MATRIX heating for convection air => heats also low-E glasses to even temperature. Tempering blower motor with inverter drive. The design is made according to the best known practices for low energy consumption; large air channels and optimized nozzle design.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese